10.105 – EFFLORESCENCE

High-Reactivity Metakaolin

Engineered Mineral Admixture for Use with Portland Cement

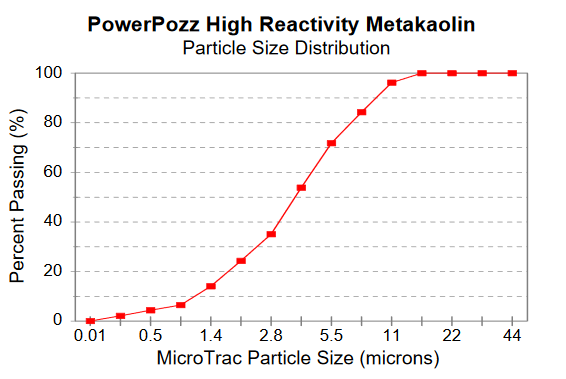

Advanced Cement Technologies’ PowerPozzTM High Reactivity Metakaolin is a manufactured pozzolanic mineral admixture which significantly enhances many performance characteristics of cement-based mortars, concretes and related products.

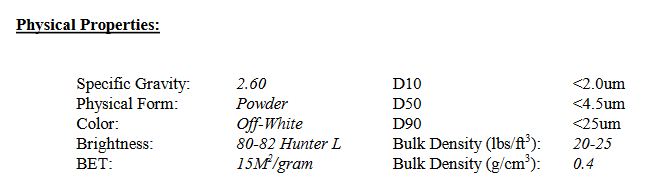

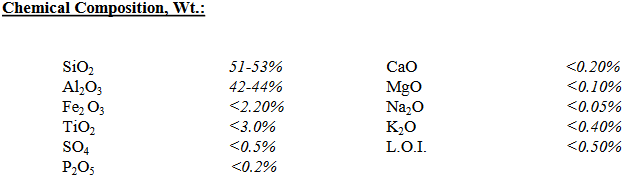

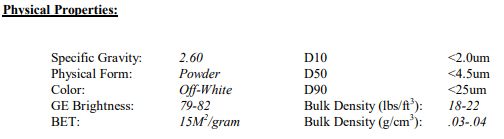

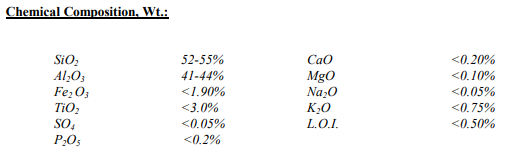

PowerPozzTM, derived from purified kaolin clay, is a white, amorphous, aluminosilicate which reacts readily with calcium hydroxide to form compounds with cementitious value. PowerPozzTM is subjected to strict process quality controls to assure product uniformity and consistent performance. PowerPozzTM is produced to 1S0 9002 Certification Standards and meets the specification of ASTM C-618 – Class N Pozzolans.

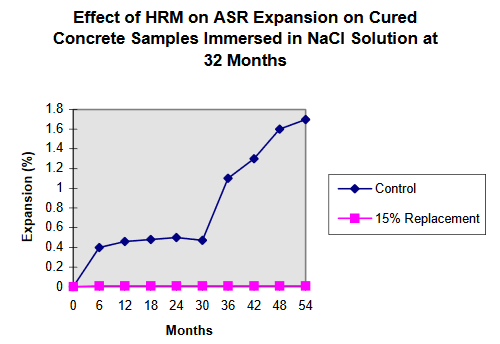

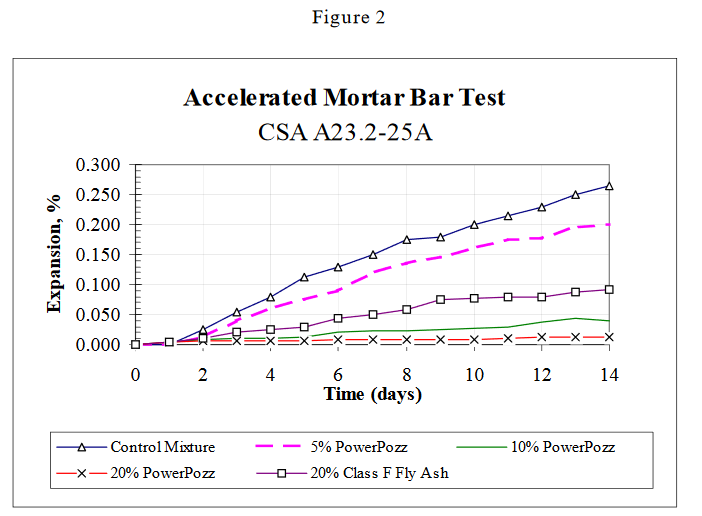

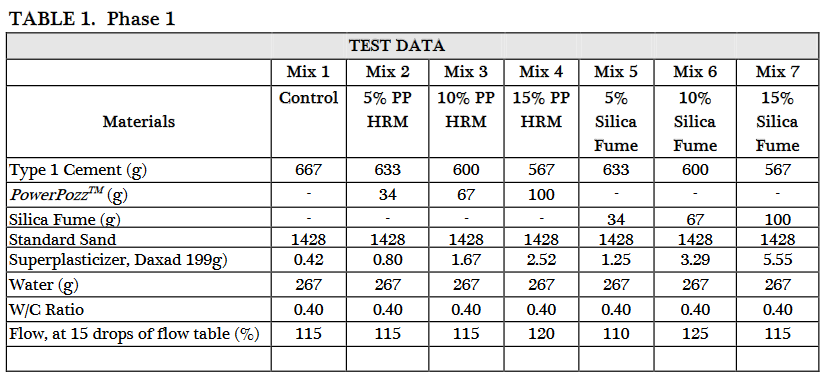

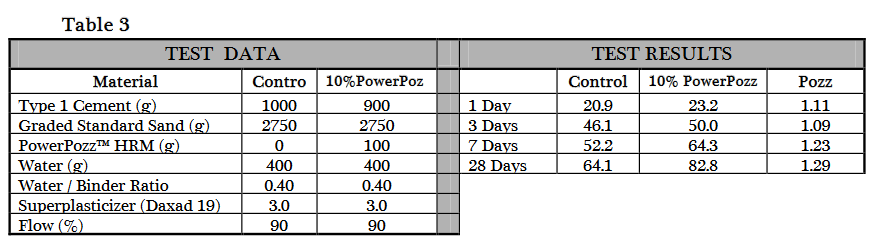

Used at 5 – 15% by weight of cement, PowerPozzTM will provide: increased strength; reduced permeability; greater durability; and is effective in mitigating efflorescence and degradation caused by alkali-silica reaction (ASR).

Problem Statement

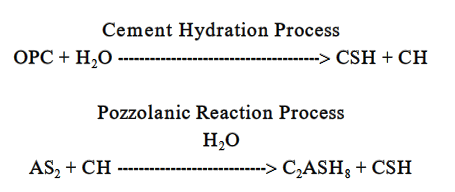

The phenomenon, commonly known as efflorescence, occurs when calcium hydroxide (free lime), a soluble reaction by-product of the hydration process of ordinary portland cement (OPC), is carried to the surface of cement-based products by migrating water. Exposed to the atmosphere, calcium hydroxide reacts with carbon dioxide to form calcium carbonate deposits which remain apparent as unsightly, whitish stains. Too often, efflorescence shows up to severely dampen the aesthetic appeal of otherwise successful masonry and composite projects.

Most common and problematic in masonry construction and architectural precast products, efflorescence is a persistent problem which has brought about a situation where masonry and precast design flexibility has been unnecessarily limited.

Two forms of Efflorescence have been identified – Primary and Secondary. They are distinguished by the point in time at which they occur in relation to the curing process.

- Primary efflorescence occurs during the curing process. Excess water in the matrix bleeds to the surface where it eventually evaporates, leaving behind deposits of calcium hydroxide crystals (Ca(OH)2) which, when exposed to the carbon dioxide (CO2) in the air, form calcium carbonate (CaCO3) in the surface pores.

- Secondary efflorescence occurs in cured concretes and composites, which are in contact with moisture or are subjected to cycles of re-wetting and drying. Moisture penetrates into, and leaches from, the matrix, dissolving soluble calcium hydroxide (Ca(OH2) that remains as a normal byproduct of portland cement hydration. Upon subsequent drying, the water, with lime in solution, can migrate to the surface (atmosphere) where, upon evaporation, leaves deposits of calcium hydroxide (Ca(OH)2 and subsequently, calcium carbonate (CaCO3).

The PowerPozzTMSolution

- Eliminate Free Lime from the system through rapid Pozzolanic Reaction,

- Increase the density and Reduce the Porosity and Permeability of the paste system,

- Reduce the Cement Content with Pozzolan Substitution 5 – 15% (the Dilution Effect).

Pozzolanic Reactivity

PowerPozzTMis a lime-hungry pozzolan that reacts with free calcium hydroxide to form stable, insoluble, strength-adding, cementitious compounds.

When PowerPozzTMHRM (AS2) reacts with calcium hydroxide (CH), a cement hydration byproduct, a pozzolanic reaction takes place whereby new cementitious compounds, (C2ASH8) and (CSH), are formed. These newly formed compounds will contribute cementitious strength and enhanced durability properties to the system in place of the otherwise weak and soluble calcium hydroxide.

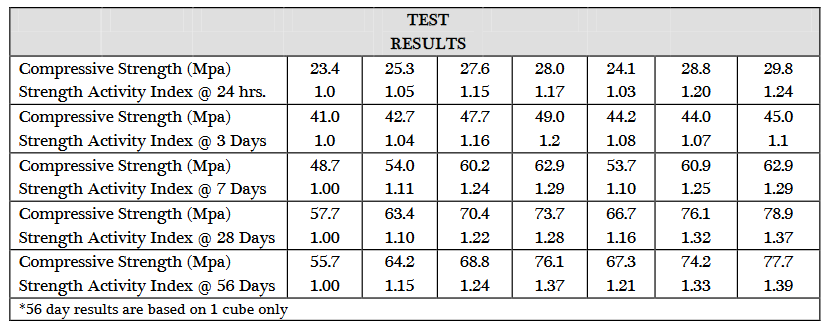

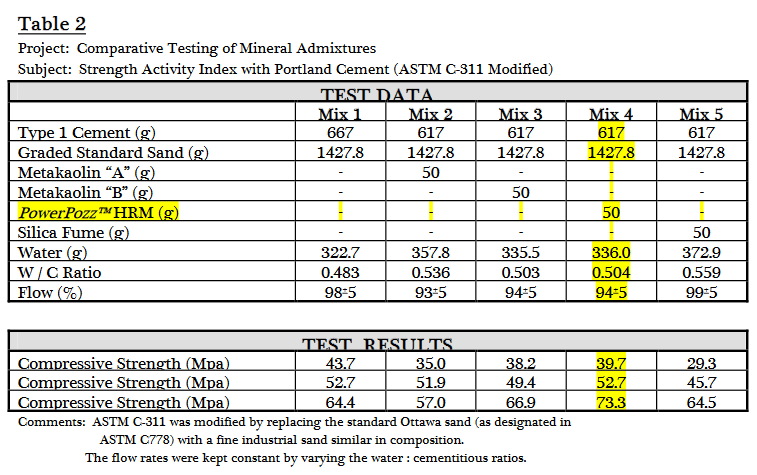

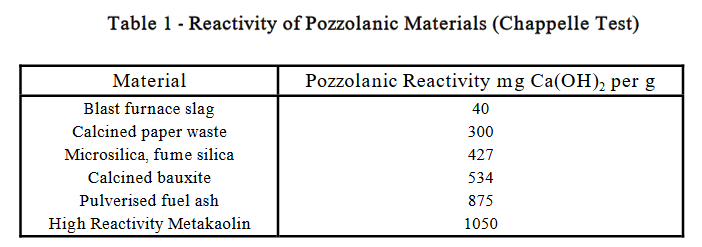

Unlike other commercially available pozzolanic materials, PowerPozzTMHRM is a quality-controlled, manufactured material. It is not a byproduct of an unrelated industrial process. PowerPozzTMhas been engineered and optimized to contain a minimum of impurities and to react efficiently with cement’s hydration byproduct –calcium hydroxide. As determined by the Chappelle test(1), Table 1 summarizes the relative reactivities of six different pozzolans, including an HRM sample(2).

Primary efflorescence can be reduced by using PowerPozzTM at 5 – 15% replacement of cement by weight. Care must be taken to follow good curing.

practices that will minimize evaporation during curing. Low water cement ratios, plastic vapor barriers, delayed demolding, high humidity (or steam curing) are now, and have long been, recommended as good concrete curing practice. The use of High Reactivity Metakaolin works to the root of the efflorescence problem by eliminating the calcium hydroxide from the system. Once fully cured, an optimized HRM-formulated product cannot exhibit Secondary Efflorescence as virtually all of the available free lime has been chemically combined by pozzolan.

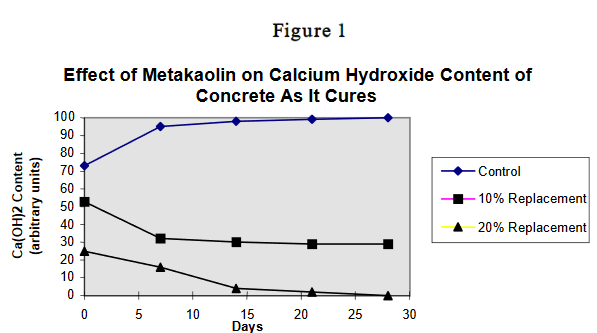

The ability of metakaolin to combine with calcium hydroxide is well-researched and documented. Larbi and Bijen(3) and Jones, et al(4) have shown that the pozzolanic reaction with pure metakaolin is rapid. In fact, it is apparent that the rate of reaction approaches that of cement hydration and subsequent lime liberation. Figure 1 shows the reaction curves and shows that metakaolin, at 20%, virtually eliminated Ca(OH)2 from the system at 14 days.

Reduced Permeability

Concrete’s porosity, pore interconnectivity, and overall permeability to fluids have direct influence on the concrete’s ultimate durability and useful service life. Where quality concretes, mortars and other cement-based products are produced with careful control of materials and water to cement ratios, performance can be significantly enhanced by the addition of highly reactive pozzolans. The addition of PowerPozzTM HRM to these materials, at a 5 – 15% replacement by weight of cement will contribute to a more compact arrangement of cementitious products where increased paste densities, mechanical interlock and paste-aggregate bond are the result. The key to maximum results here, as it is with the addition of any finely divided material to concrete in wet or dry casting processes, is a fully dispersed and homogenous matrix of ingredient materials.

In addition, the pozzolanic reaction, as described above, has a direct and significant influence on the material’s service permeability. As soluble hydration byproducts in a non-pozzolan enriched concrete are leached out by migrating moisture, they leave behind opened and more interconnected pore systems which will set the stage for an increased risk and rate of efflorescence discoloration, fading and staining. By chemically combining with calcium hydroxide, the pore system is rendered much more stable.

The surface texture of a concrete, stucco, mortar or related product can also be enhanced with a PowerPozzTMaddition. Sharper, stronger edges and details with a “tightened” surface are possible. It is conceivable that with a finer pore system on the surface, any occurrence of efflorescence or related fading of pigmented products would be less apparent as calcium carbonate deposits tend to be more obvious in products with larger, more open surface pores. These effects are principally attributed to the efficient size, shape and micropacking effect of PowerPozzTM’sclayparticles which contribute to a more dense and internally cohesive paste structure.

Cement Replacement- The Dilution Effect

PowerPozzTMhas the potential to produce high strengths in cement-based products at 5 – 15% replacement by weight of cement. As such, it is common to see increases in concrete or mortar compressive strengths (>20%) such that a further cement reduction beyond pound for pound cement replacement can be taken if strength gains of this degree are not required or beneficial. It is possible for PowerPozzTM to replace cement by weight at 1:2 to 1:3; this would, of course, require trial mixes with specific materials to confirm the exact formula. It is in this further cement reduction that the dilution effect becomes significant. This is of particular significance for stucco products (eg. where strength is of lower concern), but would need to be balanced against workability and related properties as a function of total cementitious paste content.

PowerPozzTMfeatures:

- Rapid reaction. The potential to react with more than its own weight equivalent in calcium hydroxide.

- A minimum of impurities.

- Stable-to-enhanced early strength performance (< 24 hours).

This unique package of features and benefits makes PowerPozzTMstand out within the world of admixtures as the performance leader and preferred pozzolan for use in quality and high performance architectural and structural applications – especially where engineering properties, aesthetics and durability are important.

All information, while provided in good faith, with every effort made to assure accuracy, is provided by Advanced Cement Technologies at no charge, and without warranty –express or implied. Data given, unless otherwise stated, are based on standard testing procedures which are available on request. Variations do occur in individual tests and the results stated herein cannot be taken for minima or maxima for specification purposes.

As we cannot anticipate all possible applications of our product, nor variations in manufacturing equipment, formulae, methods, or practices, we guarantee only that the product will meet the specifications of Advanced Cement Technologies at the time of sale. Advanced Cement Technologies reserves the right to change specifications should it become necessary. The product is sold without express or implied warranty, with all warranties of fitness of purpose and merchantability being disclaimed, and on condition that the purchaser is responsible for the determination of the product’s suitability for a particular purpose.

Statements concerning the possible use of our product are not intended as recommendations for use. No liability is accepted for any infringements of any existing or future patents.

All products sold, unless otherwise stated, will be subject to general sales conditions, which are supplied with all quotations and order confirmations.

REFERENCES

- LARGENT, R. Bull. Liasons Lab. Pont Chausees, v.93, 1978, pp. 63.

- New Pozzolanic Materials For The Concrete Industry ECC International – Europe.

- LARBI, J.A. and BIJEN, J.M. PhD Thesis, Delft University, 1991.

- JONES, T.R., WALTERS, G.V. and KOSTUCH, J.A. 9th Int. Conf. AAR in Concrete, v.1, 1992, pp. 485-496