Silica Fume Introduction

Silica Fume

SupplementaryCementitious Materia

The American Concrete Institute (ACI) defines silica fume as “very fine non-crystalline silica produced in electric arc furnaces as a by-product ofthe productions of elemental silicon or alloys containingsilicon” (ACI 116R). It is usually a gray colored powder, somewhat similar to portland cement or some fly ashes.

Silica fume is usually categorized as a supplementary cementitious material. This term refers to materials that are used in concrete in addition to portland cement.

Silica fume is frequently referred to by other names:

- Condensed silica fume

- Microsilica

- Volatilized silica

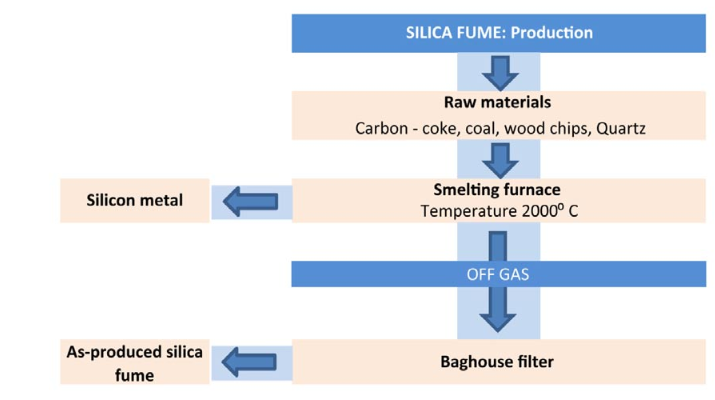

Silica fume is a by-product of producing silicon metal or ferrosilicon alloys in smelters using electric arc furnaces. These metals are used in many industrial applications to include aluminum and steel production, computer chip fabrication, and productions of silicones, which are widely used in lubricants and sealants. While these are very valuable materials, the by-product silica fume is of more importance to the concrete industry.

Densified and Undensified Silica Fume

Silica fume has historically been available in three basic product forms: undensified, slurried, and densified. There is no data available, after many years of testing, to show that any one of the product forms will perform better in a concrete mixture than any of the others.

Slurried silica fume is no longer available in the U.S. market. Undensified silica fume is available,but it is not frequently used in ready-mixed or precast concrete. Undensified silica fume is primarily used in pre-bagged products such as grouts or repair mortars.

Densified silica fume is produced by treating undensified silica fume to increase the bulk density up to a maximum of about 400 to 720kg/m3. This increase in bulk density is usually accomplished by tumbling the silica-fume particles in a silo, which causes surface charges to build up. These charges draw the particles together to form weak agglomerates. Because of the increased bulk density, this material is more economical for truck transportation.

Densified silica fume works very well in concrete. However, one caution when working with this product form is to ensure that the mixing is adequate to break up the particle agglomerations. Mixing in some types of mixers such as those that are used in dry mix shotcrete, roof tiles, or other applications where coarse aggregate is not present may not be adequate to break up the agglomerations. In those situations, an undensified silica fume may be more appropriate. Contact the Silica Fume Association for assistance in these types of applications.

REFERENCES

Information provided by US DEPARTMENT OF TRANSPORTATION –Federal Highway Administration –Silca Fume Association -April 2005